Intro

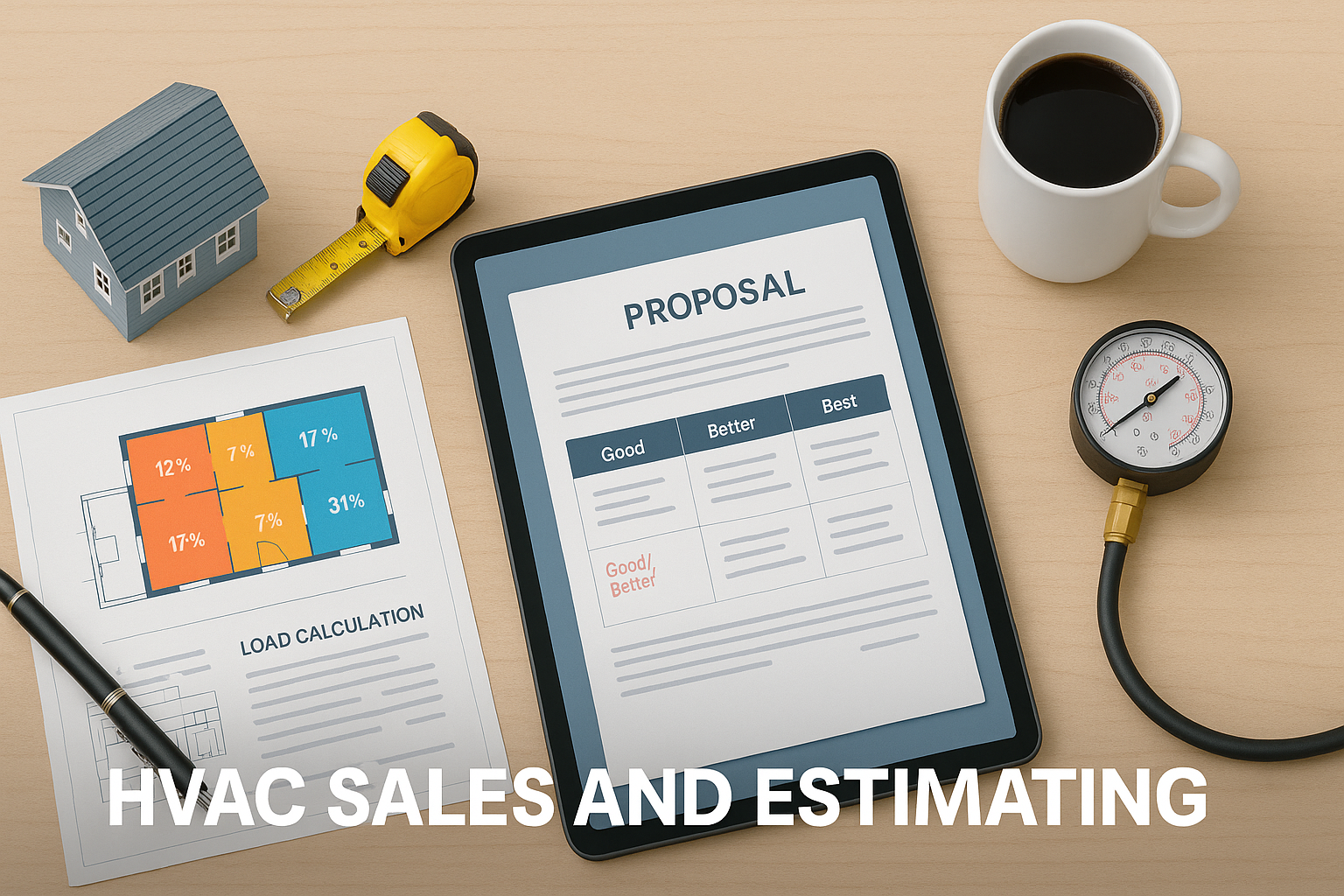

If you’re moving from tech to sales (or wearing both hats), the fastest wins come from better load calculations, tighter estimating, and proposals that make decisions easy. This guide shows how to build those skills through online HVAC education—so you can practice the math, the messaging, and the margin control from home. It’s designed for career changers, working parents, and shop owners who need a repeatable sales-estimating process. You’ll learn a practical framework for first-call data collection, how to interpret load outputs without over- or undersizing, how to package good/better/best options, and how to improve close rates ethically. We’ll also outline how online HVAC school pathways at HVACwithJB pair coursework with simulations and compliance basics (EPA 608, safety) to support confident field performance.

Sales-Estimator Fundamentals: From Lead to Commissioned System

The Three Pillars: Loads, Proposals, Close Rates

-

Accurate Loads: Right-sized equipment protects comfort, energy use, and your reputation. (Avoid “rules of thumb.”)

-

Estimating Discipline: Clear scope, labor/equipment math, and risk buffer keep margin healthy.

-

Proposal Design: Options with clear value signals reduce friction and boost acceptance.

Pro Tip: Treat your sales workflow like commissioning—objective inputs, documented assumptions, and a verifiable result. That’s the backbone of credible online HVAC training and real-world selling.

Mini-Framework: L.O.A.D.S. for First-Call Success

L—Location & Envelope: Gather address, orientation, year built, insulation/air sealing notes, window types/shading.

O—Occupancy & IAQ: People count, schedules, pets, health/IAQ concerns (filtration/MERV, humidification, ventilation).

A—Appliances & Gains: Lighting, cooking, home office gear, server closets—internal loads change sizing.

D—Ducts & Delivery: Size, material, leakage, static pressure history; room-by-room comfort notes.

S—Site Photos & Safety: Equipment access, pad, electrical, condensate path; note hazards for OSHA compliance.

Capture this data in a consistent digital form (tablet checklist). Your online HVAC school modules will reinforce methodical collection so you can run a quick preliminary check, then formal calcs back at your desk.

Scenario: “Hot Bonus Room, 2.5-Ton Swap, Or 3-Ton?”

A homeowner wants a straight change-out of a 2.5-ton split. The bonus room added last year faces west with new windows. During your L.O.A.D.S. walkthrough you record: orientation (W/SW glazing), window SHGC, attic R-value, and occupancy (two teens home after school with gaming PCs). The formal load shows total sensible higher than before, but static pressure history is also poor. Instead of a “3-ton and hope,” you propose:

-

Duct remediation + 2.5-ton high-efficiency (meets load, improves airflow), or

-

Mini-split for bonus room + right-sized main system (zoned comfort).

Result: Better comfort, lower energy use, and fewer callbacks.

Residential Load Calculations 101 (for Salespeople)

You don’t need to be a PE to understand load drivers. What matters:

-

Climate & Orientation: Solar gains can swing loads materially; west exposures often drive peaks. (DOE/Energy Star guidance emphasizes orientation in sizing practice.) The Department of Energy’s Energy.gov+1

-

Envelope & Infiltration: Insulation levels, air leakage, and window performance push sensible loads up or down.

-

Internal Gains: People, lighting, electronics; small homes with heavy internal loads can surprise you.

-

Ventilation/IAQ Targets: Higher ventilation or filtration standards (e.g., MERV 13 for IAQ) may alter fan selection and external static.

ASHRAE’s Fundamentals/Load Calculation texts are the industry baseline; your goal as a salesperson is to interpret outputs and explain why “right-sized” beats oversizing. ASHRAE+2ASHRAE+2

Warning: Square-feet-per-ton shortcuts and generic online BTU charts lead to oversizing, humidity issues, and short cycling. Use recognized methods and document assumptions. (Contrast with rules-of-thumb noted widely in industry commentary.) Energy Vanguard

Manual vs. Software: What You Actually Need

| Approach | Pros | Cons | Best Use |

|---|---|---|---|

| Spreadsheet/Manual Inputs | Teaches fundamentals; transparent assumptions | Time-consuming; easy to mis-key | Training, small/simple homes |

| Software (Manual J/S engines) | Fast, consistent, stores libraries, easy revisions | Garbage-in/garbage-out if your input is sloppy | Production estimating; option modeling |

| Internal Sizing Rules (No formal calc) | Fastest | High risk of comfort issues & callbacks | Avoid—use only as a pre-quote sanity check |

Estimating That Protects Margin

Estimating isn’t just price; it’s scope clarity and risk control. Build a template that locks in:

-

Labor math: Crew size × hours × burden (not just wage), including travel, loading, and cleanup.

-

Material/equipment: Include pads, controls, line set/adapters, disconnects, surge protection, low-voltage, fasteners, sealants.

-

Permits & inspections: Include time and fees.

-

Duct/airflow corrections: Price for static pressure fixes, balancing dampers, returns, and sealing.

-

Commissioning time: Measure superheat/subcooling, airflow (TEET or fan tables), and controls verification.

Fast Checklist: Scope, Risks, and Escalation

-

Scope: Demo, install, duct mods, electrical, condensate, controls/BAS tie-in, thermostat training.

-

Risks: Asbestos/vermiculite, rotten platforms, concealed ducts, line-set path, structural constraints.

-

Escalation: Commodity volatility clause for copper/refrigerant, plus re-quote terms after X days.

Example: “Price assumes existing line set is reusable and passes pressure test. If replacement is required, add $___.” This protects you without surprising the homeowner.

Proposals That Win: Clarity, Options, Proof

A strong proposal is readable, option-oriented, and confidence-building:

-

Executive Summary: Restate the problem in the homeowner’s words; anchor the load result (sensible/latent) and airflow plan.

-

Good/Better/Best Options: Each with SEER2/HSPF2 ratings, warranties, and IAQ adders (filter cabinet, UV, ERV where appropriate).

-

What’s Included: Commissioning steps, duct sealing points, thermostat training, first maintenance visit.

-

Evidence: Before/after photos of similar projects; short case study; references.

Compact Comparison Table: Good/Better/Best

| Option | System | Why It Fits the Load | Comfort/IAQ | Warranty | Investment |

|---|---|---|---|---|---|

| Good | Right-sized single-stage | Meets calc with improved ducting | MERV 11 cabinet | 10-yr parts | $$ |

| Better | Two-stage | Longer runtime for dehumidification | MERV 13 + ECM | 10-yr parts + labor | $$$ |

| Best | Inverter | Tight load match, quiet, top comfort | MERV 13 + ERV (as needed) | 10-yr parts + labor | $$$$ |

Pro Tip: In online HVAC education, practice turning load results into a 3-option layout with a one-sentence “fit” statement for each. That sentence sells.

Close Rate Mechanics: From “Bid Reader” to Trusted Advisor

-

Diagnose, then prescribe: Lead with findings (duct static, room-by-room issues, measured temps).

-

Teach simply: One minute on why oversizing hurts humidity; show the specific data you gathered.

-

Offer choices, not confusion: Three options with a clear default recommendation.

-

De-risk the decision: Spell out commissioning and first-year service.

-

Follow-up cadence: Same-day summary, 48-hour check-in, one-week “any questions?” touch.

Pro Tip: Track proposal turnaround time, option mix chosen, and follow-up interval. These correlate heavily to close rate improvements in real shops.

Outcome Roadmap

By leveraging online HVAC training modules alongside shop experience, here’s what competency progression looks like:

Week 2

-

Perform a complete L.O.A.D.S. walkthrough and gather inputs consistently.

-

Run a basic residential load with software; interpret sensible vs. latent; select tonnage confidently.

-

Draft a one-page “Good/Better/Best” proposal with accurate scope bullets.

Week 6

-

Build full estimates with labor burden and risk clauses; include duct/airflow corrections.

-

Present proposals with plain-language load summaries and commissioning checklists.

-

Track close rates and reasons won/lost; tighten follow-up process.

Week 12

-

Handle “edge cases” (bonus rooms, additions, mixed-mode IAQ) with alternate strategies (mini-split, zoning, duct remediation).

-

Coordinate with installers for smooth handoff; verify commissioning data (superheat/subcooling, airflow) matches proposal intent.

-

Demonstrate measurable improvements: lower callbacks, higher margin, higher close rate.

Certification & Compliance

-

EPA 608: Required by federal law for anyone who services or disposes of equipment containing regulated refrigerants. If you’re moving into sales/estimating from the field—or plan to handle refrigerant at all—get certified and stay current with best practices. EPA+2EPA+2

-

Prepare with [EPA 608 Refrigerant Usage Certification] at HVACwithJB. HVAC with JB

-

-

NATE: Valuable industry credential (not a legal requirement) that signals competence to employers and customers; continuing education helps maintain it.

-

Safety/OSHA basics: Jobsite observations (access, electrical, ladders, PPE) should appear in your first-call notes; they influence installation time and risk.

-

Load Standards: ASHRAE handbooks and DOE/Energy Star materials reinforce right-sizing principles and climate data use in load calcs. ASHRAE+2ASHRAE+2

Tools & Study Setup

Home Lab Essentials (Sales/Estimating Edition):

-

Tablet/2-in-1 with a stylus, camera, and cloud forms for L.O.A.D.S. data capture

-

Tape measure, laser measurer, anemometer, static pressure kit (for joint ride-alongs), flashlight

-

Software access for Manual J/S style calcs; PDF editor for proposals; e-signature tool

Simulation Expectations:

HVACwithJB’s online HVAC school modules use stepwise lessons, practical assignments, and virtualized exercises so you can rehearse data collection, load entries, and proposal building—before you face a time-boxed sales call. HVAC with JB

Time-Blocking Tips:

-

60 min/week content, 60 min/week practice (one mock proposal), 30 min/week review of closed/won and lost deals.

-

Keep a “Findings Library”: photos and annotated diagrams you can reuse in proposals.

Common Mistakes & Fixes

-

Relying on rules of thumb.

Fix: Use recognized methods and document inputs; reference orientation/envelope specifics. ENERGY STAR -

Skipping duct/airflow notes.

Fix: Record static pressure history and return sizes; price fixes up front. -

One-price proposals.

Fix: Offer good/better/best with a recommended default. -

No commissioning line items.

Fix: Include and explain superheat/subcooling checks, airflow verification, and controls setup. -

Underestimating labor burden.

Fix: Calculate fully loaded labor (wage + taxes + benefits) and travel/setup time. -

Weak follow-up.

Fix: Use a 0/2/7-day cadence with brief value-focused messages. -

Compliance confusion.

Fix: Clarify EPA 608 (required for handling refrigerants) vs. NATE (optional but respected). EPA

Internal Links to Explore

-

[EPA 608 Refrigerant Usage Certification] — exam prep + proctored online testing. HVAC with JB

-

[HVAC/R Apprenticeship Training Program] — industry-aligned, DOL-registered related training. HVAC with JB

-

[Building Automation Systems (BAS) Program] — controls fundamentals to advanced strategies. HVAC with JB

-

[Chiller Mechanic Training Program] — specialization pathway for large-tonnage systems. HVAC with JB

-

[Commercial Refrigeration Training Program] — supermarket/rack and commercial casework foundations. HVAC with JB

-

[Programa HVAC en español] — Spanish-language program hub. HVAC with JB

References

-

[Section 608 Technician Certification Requirements — US EPA] EPA

-

[ASHRAE Handbook — Fundamentals (overview)] ASHRAE

-

[ENERGY STAR: Right-Sized Air Conditioners (fact sheet)] ENERGY STAR

FAQ

1) Do I need to master Manual J math to sell HVAC effectively?

No. You need to collect inputs accurately and understand the outputs well enough to justify equipment selection. Software plus a disciplined L.O.A.D.S. walkthrough is sufficient for most residential jobs.

2) How does online HVAC education help my close rate?

Structured modules let you rehearse load entries, proposal templates, and objection handling. Practicing these steps lowers your turnaround time and improves clarity—two big drivers of close rates.

3) What if the customer demands a bigger tonnage “just in case”?

Explain sensible/latent loads and humidity. Oversizing can cause short cycling and poor dehumidification. Show the load report and a “Better” option (e.g., two-stage or inverter) that addresses comfort without oversizing.

4) When does EPA 608 apply to sales/estimating roles?

If you recover, charge, open, or dispose of systems with regulated refrigerants, you must hold EPA 608. If you’re strictly selling/estimating and never handle refrigerant, it may not be required—but it enhances credibility. EPA

5) How do I price duct fixes without losing the job?

Document the issues (photos, static readings), show the comfort/efficiency value, and present them as part of the base solution—not an afterthought.

6) What’s the simplest way to present options?

Good/Better/Best on one page with load fit, comfort features, warranties, and investment. Default to the Better option for balance.

7) Can online coursework count toward a broader career path (controls, refrigeration)?

Yes—HVACwithJB’s pathways include BAS/controls, chiller mechanic, and commercial refrigeration; the sales-estimating skillset pairs well with these tracks. HVAC with JB+2HVAC with JB+2

8) Are Spanish-language options available?

Yes. See the Spanish program hub for core coursework in Spanish. HVAC with JB

Ready to turn better loads and clearer proposals into higher close rates? Choose the path that fits your schedule:

-

Enroll in a program to build a complete, job-ready skillset.

-

Start the Free Sample Course to see how the platform works and try a lesson.

-

Contact Admissions for help mapping your sales-estimating goals to the right coursework.